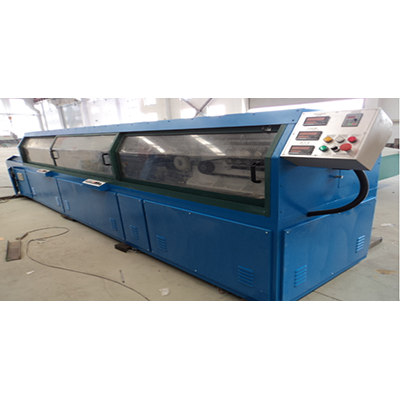

WLZB-4/16X Paper Wrapping Machine Technical Parameter

(servo control)

1. Notes to model code:

WLZB-4/16X Paper Wrapping Machine

WLZB —-Horizontal Crawling Traction Paper Lapping Machine

4/16 —– one product line with four paper tapping heads, each taping head may

wrapping 4 layers of paper, so it can wrap Max.4*4=16 in total

X ——- Number of paper layers

2. Main data

product scope Copper / Aluminum rectangular wire

section area 5~80 mm²

Line speed 8~16m/min, step less adjustable

Lapping pitch 10~32 mm, step less adjustable

Lapping head rated speed 500~700 rpm/min(According to the wire gauge

and paper)

Paper Pad OD 330 mm

Paper Pad ID 75 mm

Paper Pad width 10~32 mm

Paper thickness 0.040~0.125 mm

3. Scope of supply

Main machine 1 unit

FS pay-off unit 1 unit

LS take-up unit 1 unit

Electric control system 1 set

Accessories 1 set

Foundation layout 1 set

Anchor bolts 1 set

Technical documents 1 set

ü technical specification

ü operation instruction

ü installation instruction

ü lubricant chart

ü maintenance scheme

ü trouble shooting sheet

ü spare part list

ü operation manuals for PLC and drivers

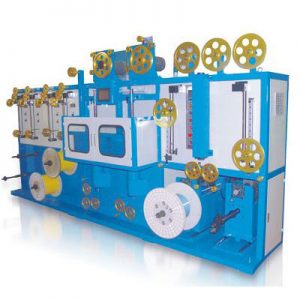

4. PS pay off 1 unit

lifting and lowering by electric lift wooden dish,aerodynamic damping pay off

Type Pay off by bobbin moving

Up/down Motor

Clamping Shaft

Carrying weight Max. 800 kg

5. WLZB-4/16X main machine components list in detail:

5.1

straightening device 1 set

Straightening rollers 10 pieces

Roller diameter 47 mm

Roller distance 70 mm

5.2

Paper tapping head 4 set

Wrap direction Taping head rotation direction can be adjust

turn positive or negative

Paper Pad OD 330 mm

Paper Pad ID 75 mm

Quantity of pad on each head 4 PCS.

Locking mode of paper pad locknut

Position of paper pad 4 PCs on one plane

Adjust angle of paper wrapping rotating roller

Lapping pitch 10~32 mm, stepless adjustable

Pitch excursion ±0.2 mm

Lapping head rated speed 800 rpm/min

Lapping head biggest production speed 500-700 rpm/min

Number of lapping head 4 piece

Lapping layer 16 layers

Tension control constant tension, Automatic adjust by Mechanical

Hollow diameter 35 mm

Steel part with antisepsis treatment

Kraft break detector stop with optic electric inductive during

normal operation, the main machine will stop

work while the paper tape finished or tape

fracture,sliding inertia length is about 150 mm

Transmission device Servo motor driver

5.3

Pulling Caterpillar 1 set

Caterpillar length 1120 mm

Belt material Rubber

Caterpillar drive Servo motor driver

Clamping method Pneumatic

Max. Pulling force 500kgf

Max. Opening distance between belts 40 mm

Synchronization Servo motor control

5.4

Meter counter 1 set

Type Electrical

Length method by wheel that directly contacts wire

Length measuring Stop the machine at setting length

6. LS take up unit 1 unit

Type take up by bobbin moving

Drum diameter provide by USER

Barrel diameter provide by USER

Drum width provide by USER

Bore diameter provide by USER

installing bobbin with pintail of bearing

Lifting, lowering bobbin motor

Wire traversing by servo motor、screw to wire traversing

Take up by frequency conversion motor, inverter control tension

Carrying Weight max 800kgs

Reviews

There are no reviews yet.