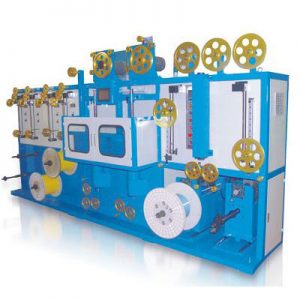

PLC triple layer tape wrapping and sintering line

- Technical parameter:

Application: horizontal type tape wrapping line used for polyester, BOPP, polyimide-FEP, PI film, Kapton, Upilex or other material. The line equipped with driven pay off, triple tape wrapping, online sintering, online testing, and online coiling, can finish all the production in one process, greatly improve wire quality, reduce material waste and labor cost.

Voltage: 3P 380V 50Hz as standard, or customized

Line height: 1120mm

Product range:conductor 0.5 to 2.0mm.

Reel size: pay off:400-630

Coil size: 350mmOD, 200mm ID, 50-150mm Height

Tape size: OD max 250mm, width 5-16mm, height 100mm, thickness 0.01mm-0.1mm

Line speed: 3-60m/min, line speed= RPM * lay length /1000

Taping overlapping rate: 0-67%, lay length set on PLC

Lay length tolerance: 1%

Tapping direction: S, Z both

Tapping line direction: from left to right or from right to left.

Machine color: main machine grey RAL7035, machine base black RAL7026, door and safe color orange RAL2003, can be changed on customer’s request.

- Machine components:

| No. | Item and specification | Quantity | remark |

| 1 | 630 motorized pay off with tension dancer | 1 set | |

| 2 | PLC controlled spooler tape wrapping machine | 3 PCs | |

| 3 | 1.5m auto sintering oven | 1 set | |

| 4 | 400 double wheel capstan | 1 set | |

| 5 | 15KV high frequency spark tester | 1 set | |

| 6 | Diameter tester (shanghai) | 1 set | |

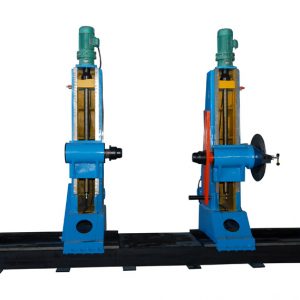

| 7 | 2m vertical accumulator (capstan wheel 200) | 1 set | |

| 8 | 1.5m cooling water though(with wiper) | 1 set | |

| 9 | 630 shaft-moving dual take up | 1 set |

- The brands of main parts:

| Item | Model | Brand | Origin place | remark |

| Motor | Siemens Beide | China | ||

| Inverter | Sinee | China | ||

| PLC | S7-200 | Siemen | Germany | |

| HMI | WEINVIEW | Taiwan | ||

| Tension controller | Weizheng | China | ||

| Main shaft bearing | SKF | Switzerland | ||

| Switches and knots | Schneider | France | ||

| Relay | Schneider | France | ||

| Air switch | Chint | China | ||

| contactor | Shilin | Taiwan |

- Details of every parts:

Item 1. 630 shaftless driven pay off

structure: shaftless type driven pay off, electrical lift, hand wheel tighten.

Reel size: Max.Ф630, MinФ400

Reel lift: electric screw rod lifting

reel tighten: hand wheel tighten

tension control: counter weight tension control, adjust pay off tension through moving weight block, potentiometer angel given voltage signal to control the pay off motor, tension range 0-2000g.

wire break test: wire break machine auto stop.

guiding pulley: Ф180 guiding pulley set, 3 grooves + 2 grooves.

driving motor: 1.5KW motor + inverter control.

bearing weight: Max.300kg:

Item 2. 250 OD spoole type tape wrapping machine with PLC control

Structure: horizontal type machine with spooler taping head. Motor+ inverter control, with magnetic tension control.

Tape:polyester, BOPP, polyimide-FEP, PI film, Kapton, Upilex or other material

Rotating speed: Max 2500RPM, practical 2300RPM

Line speed: 3-60m/min, line speed= taping pitch *RPM/1000

Spooler type tape: Max 250mm OD; center bore 76mm; tape width 5-16mm, height 100mm; thickness 0.01-0.1mm. tape weight less than 8kg.

Lay length: 8-20mm, over lapping rate 0-67%, set on HMI, tolerance: +/- 1%.

Wire thread tube diameter: 12mm

Tension control: 1.2KGM/12NM, DC24V magnetic clutch, magnetic clutch auto trace needed tension, tension control keep stable from full pad to empty pad, no need manual adjust tension. Tension range: 50~1200g

Tape storage length: 200mm

Main power: 1.5KW motor + inverter

Taping shaft: 40Cr material, shaft use grinding, high frequency conditioning treatment, strong wear-resisting, non-deformation under high speed running and heavy loading. With SKF bearing, no resistance and waggle under high speed running, machine is much durable.

Wrapping head: use static balanced installation, after installed, use dynamic balance treatment, ensure wrapping head works stable and at high speed, avoid tension instability.

Wire thread: with wire inlet and outlet “#” guiding pulleys, also with guiding pulleys after tape wrapping, reduce core wire shaking influence on wrapping tension.

Spooler type tape replace pad type tape, longer tape, reduce machine stop time, and wire joint, stable tape wrapping tension.

PLC auto control system: Siemens controller, VEINVIEW HMI, high sensitivity.

HMI monitor: online monitor line speed, wrapping pitch, overlapping rate, tape usage amount, wrapping RPM, take up length, failures and so on.

Auto alarm: wire break/tape break/tape use up/length reach/machine failure machine auto alarm, you can set weather stop or not.

Tension auto trace: according to set wrapping tension, PLC auto trace wrapping tension; according to set line speed, machine auto accelerate or decelerate; according to set line speed and wrapping pitch machine auto trace.

Auto recording: PLC auto record machine start and stop time, unit time productivity, total production, the failures, recording setting data for different cable size, easy for operator to know the machine working state.

Single/linked work: operator can choose machine parts single work or linked work.

Electrical cabinet cooling: cooling fan exhaust heat out

Door lock: safe door open, electric cabinet power off; only under test running state, machine can start when door open.

E-stop: when emergency situation, we have E-stop button, the machine can stop in 2 second.

Machine inner wiring use international standard wiring, with clear mark, ensure safety, easy to checking and repair.

Item 3. 1.5m auto feedback sintering oven

application: tape sintering

Length: 1500mm

heating temperature: normal temperature to 500℃, working temperature 150-350℃

heating power: 8KW

heating elements: 304 high temperature heating tube.

Oven cover: inner part SUS304 stainless steel, outer part steel board.

temp control: RKC temp controller to control the temp.

temp testing: pure copper as testing point, thermocouple testing the inner air temperature.

testing section: 1 section

heating protection: heating preserve thickness>40, surface temperature <70℃

energy saving: use SCR relay to adjust heating temperature.

intelligent control: protect the wire when stop the machine, machine start, oven in; machine stop, oven out; avoid wire over-heating, when machine stop.

inlet and outlet pulley: install guiding pulley, avoid wire sheaking and harm.

safety guard: short circuit protection, all the terminal out of the oven, easy to check.

Item 4. 400 dual wheel capstan.

Capstan wheel: OD 400, groove 381.5, groove perimeter 1200mm; Aluminum Magnesium alloy material with water-proof treatment; grooves: 4~6pcs.

Products range: 0.5-4.0mm

Line speed: 12-50m/min, according to the request.

Capstan cover: open type without cover

Shift gear: inverter continuous available.

Driving power: 3.7KW, configure according to capstan speed.

Reviews

There are no reviews yet.