HOOHA Paste Extrusion Related Equipments

We have all machines for paste extrusion system.

Blender

Blender mixes raw PTFE powder and lubricant (naphtha) at the first step of paste extrusion process.

Our blender has a hollow cylinder (bottle holder) which has a plastic bottle inside. The cylinder rotates in two ways — circumferential and axial direction. Usually the plastic bottle is made of polyethylene or PET. Rotation and time are adjustable. Because of this mechanism our blender does not cause particle shear, and it hardly grows small ball like lumps.

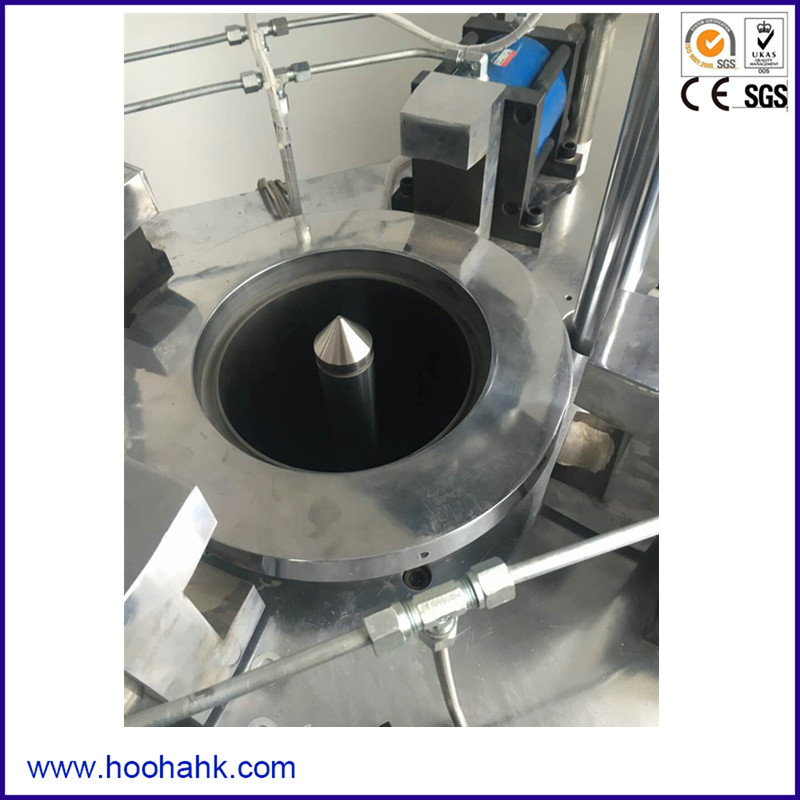

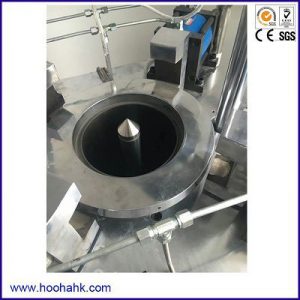

Pre-former

Before extruding, blended raw PTFE have to be pre-formed.

Pre-former forms blended PTFE powder into a clolumn or a cylinder with certain pressure.

Maxmum length of formed material is 1000mm (approx. 40 inches).

Specification

| Item | Unit | Specification |

| Cylinder inner diameter | mm | 16 to 250 |

| Cylinder length | mm | 600 to 2400 |

| Number of cylinder | 1 to 3 | |

| Drive system | Standard equipment | Hydlauric vertical pressurization |

| Heating | Optional equipment | Band heaters |

| Feeding unit | Standard equipment | Electric Feeder |

| Optional equipment | Air vibrator |

Oven for drying and sintering

Extruded PTFE still has lubricant and is soft an fragile. Therefore it must be sinterd in the next step. Sintering temperature is 100 to 500 degree Centigrade.

Our drying and sintering oven has a stable heat control system.

Length of the oven is 4 to 20m.

Drying capstan unit

It is a lubricant vapouring unit which is often set in wire covering line.

Other equipments

For PTFE sheet and film, PTFE is extruded in form of tube, bead or flat plate. It requires a calendar roll system and a tentor system.