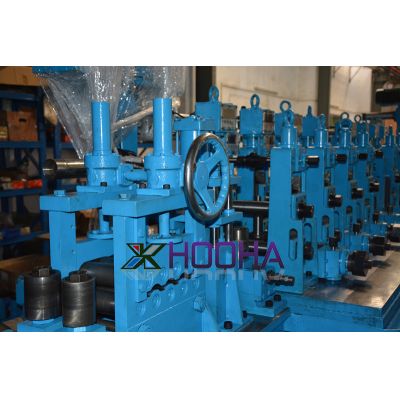

High Frequency Pipe Mill Line

1.pipe O.D(round):127mm-377mm(Φ0.5~ Φ2.5inch)

2.Square pipe:100X100mm-300X300mm

Craft Flow:

uncoiling→ shearing and butt welding→ material accumulating→ flattening→ forming system→

high frequency induction welding machine→inside and outside burr removing frame→water cooling system→sizing system→leveling system→speed testing→Turkish frame→saw cutting→

running out table

Main components:

| 1. | coiler |

| 2. | Accumulator |

| 3. | Shearing and butt welding machine |

| 4. | Forming machine |

| 5. | Roller System of Forming |

| 6. | Seam Guide |

| 7. | High Frequency Induction Welding Machine |

| 8. | Roller System for Moving |

| 9. | Burr Removing Frame(Inside and outside) |

| 10. | Water cooling system |

| 11. | Sizing machine |

| 12. | Roller System of Leveling |

| 13. | Speed Testing Wheel |

| 14. | Turkish Frame |

| 15. | Auto flying saw controlled by Computer |

| 16. | Run-out table |

| 17. | Electric control Equipment18 |

| 18 | High frequency welding machine |

Basic necessaries for the clients

Steel strips | material | Low-carbon steel, low alloy steel:,σs≤345mpa,σb≤610mpa |

| I.D | Φ350~Φ450mm | |

| O.D | Φ600~1000mm | |

| Width | 40~200mm | |

| Thickness | 0.5-1.8mm | |

| Maximum. weight | ≤1000KGS |

Necessary accessories prepared the clients :

| 1 | Workshop, Foundation construction |

| 2 | electric appliance work,civil engineering and necessary materials. |

| 3 | Electric connection wires and cables ,pipes(including connectors) from Power supply, air supply,water supply and hydraulic station to each equipment(control table,button station) of the production line |

| 4 | Auxiliary machine :fer example lifting equipment,air compressor,air storage tank,water pump,high-pressure pumps for pipe welding machine cooling, cooling water pools for pipe-welding machine and high frequency electric equipment, volume 35m3with water pipe, water pressure meter and valve |

| 5 | Auxiliary parts and low value consumable items :for example:steel strip,welding strip, blades,Lubricating oil, cycle oil, gear box oil test run material, magnetic rod, bearing etc. |

Descriptions:

| Packaging | Sea worthy packing, the mechanical parts are in nude pack, and the electrical arts and the spare parts are simply packed | |||||||

| Loading Port | SHENZHEN | |||||||

| Containers. No | Roughly estimated about each 6no of 40GP | |||||||

| Type of payments | T/T L/C | |||||||

| Lead Time | 90 days after deposit for pipe making machine made in China | |||||||

| We are make the products according to the customers.. | ||||||||

| Item | Pipe O.D (Round) | Square Pipe | Wall Thickness | Max. Speed | Main Motor | H.F. Welder | ||

| HH-16 | Φ0.3~ Φ1.0inch (Φ8mm~Φ25mm) | 7×7mm 20×20mm | 0.3 ~ 1.2mm | 100m/Min | 22Kw | 60Kw | ||

| HH-25 | Φ0.3~ Φ1.2inch (Φ8mm~Φ32mm) | 7×7mm 25×25mm | 0.3 ~ 1.5mm | 90m/Min | 37Kw | 100Kw | ||

| HH-28 | Φ0.5~ Φ2.0inch (Φ13mm~Φ50mm) | 10×10mm 40×40mm | 0.5 ~ 1.8mm | 90m/Min | 75Kw | 100Kw | ||

| HH-32 | Φ0.5~ Φ2.5inch (Φ13mm~Φ63.5mm) | 10×10mm 50×50mm | 0.5 ~ 1.8mm | 90m/Min | 110Kw | 150Kw | ||

| HH-50 | Φ0.8~ Φ3.0inch (Φ20mm~Φ76mm) | 16×16mm 60×60mm | 0.7 ~ 3.0mm | 80m/Min | 132Kw | 200Kw | ||

| HH-60 | Φ1.2~ Φ4.0inch (Φ32mm~Φ102mm) | 25×25mm 80×80mm | 1.0~ 3.5mm | 70m/Min | 160Kw | 200Kw | ||

| HH-76 | Φ1.0~ Φ5.0inch (Φ25mm~Φ127mm) | 20×20mm 100×100mm | 1.0~ 3.5mm | 70m/Min | 185Kw | 200Kw | ||

| HH114 | Φ1.6~ Φ5.0inch (Φ40mm~Φ130mm) | 35×35mm 100×100mm | 1.5~ 5.0mm | 60m/Min | 160Kwx2 | 400Kw | ||

| HH155 | Φ2.0~ Φ6.0inch (Φ50mm~Φ155mm) | 40×40mm 120×120mm | 1.5~ 5.0mm | 60m/Min | 160Kwx2 | 400Kw | ||

| HH165 | Φ2.0~ Φ7.6inch (Φ50mm~Φ195mm) | 40×40mm 150×150mm | 2.0~ 6.0mm | 45m/Min | 200Kwx2 | 500Kw

| ||

| HH219 | Φ3.5~ Φ8.60nch (Φ89mm~Φ219mm) | 70×70mm 170×170mm | ||||||

Reviews

There are no reviews yet.