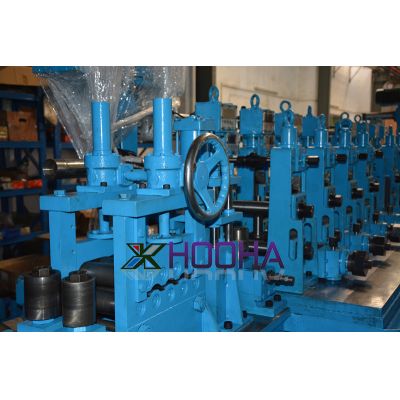

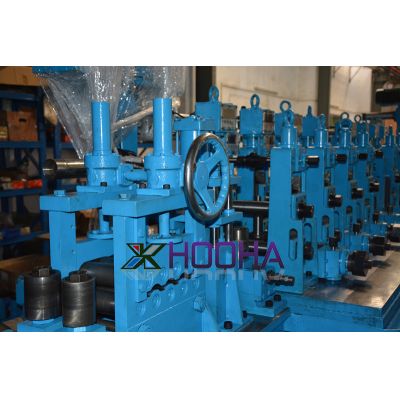

165 Tube mill Line

Raw material (Steel Strip) in form of a coil is uncoiled and fed into forming section passing through the equipment of entry section.

Entry section enables the tube mill to run continuously by using strip joining and accumulation equipment. Tube is formed in round shape passing through a set of driven and idler rollers of forming section before welding.

In welding section tube is longitudinally welded by using high frequency induction welding method.

Outside bead is removed and formed in shape of scrap. The weld seam is ironed and tube passes through the cooling section.

In sizing section, tube is formed to specified size and converted into specified shape. After sizing, tube is cut to specified length by using flying cutting equipment and delivered in collecting troughs passing through run out conveyor.

| Material to be processed | Carbon Steel, strip coils of weld able grade with max. 0.2% carbon |

| Type | Round, Square & Rectangular pipe |

| Pipe O. Diameter | |

| Round Tube | 76.2mm – 165.1mm |

| Square Tube | 60 x 60 – 130 x 130mm |

| Rectangular Tube | 40 x 80 – 120 x 140mm |

| Wall thickness | 2.0 mm – 6.0 mm |

| Pipe length | 6.0 m – 12.0 m |

| Line Speed | Max. 60 m/min |

| Welding Method | Solid State High Frequency Welding 500kW |

| Forming Method | Bottom line of tube constant for all sizes |

Reviews

There are no reviews yet.